Customised design, corrosion-resistant, grooves for better lubricant distribution. High... more

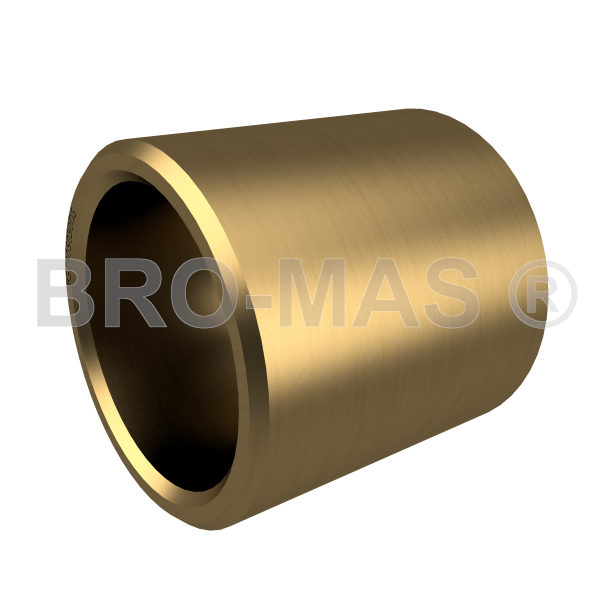

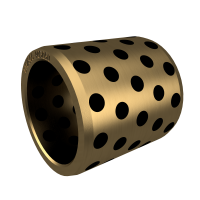

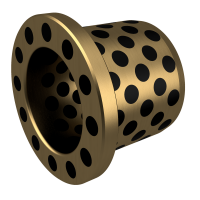

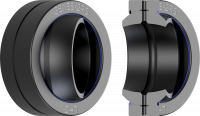

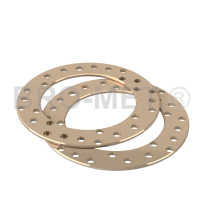

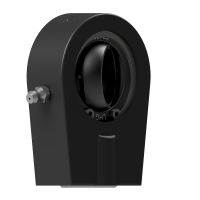

Product information "BRO - MAS® Cylindrical bushing BSZ"

Customised design, corrosion-resistant, grooves for better lubricant distribution. High loads, impact loads, wear-resistant, corrosion-resistant.

BRO-MAS is a plain bearing requiring maintenance, is suitable for operation in contaminated environments, has good corrosion resistance, and is insensitive to shock loads. Oil or grease lubrication is needed. Additional lubrication grooves or holes significantly reduce relubrication intervals and improve lubricant distribution. (IS=Internal lubrication; AS=External lubrication; AIS=External and internal lubrication; OS=Without lubrication)

Materials

| Support material/Carrier material | CuZn25Al5 (Standard alloy) |

Product Properties

| Maintenance | maintenance required |

| Static load | ≤ 200 N/mm² |

| Dynamic load | ≤ 150 N/mm² |

| Sliding speed | ≤ 10 m/s |

| Friction value | 0,09 up to 0,15 µ |

| Temperature strain | -40 up to +300 °C |

| max. pv-value | 1,8 N/mm² x m/s |

| Hardness | 190 - 220 HB |

Tolerance details

| Housing ø | H7 |

| Bushing inner ø after mounting | E7 / s6 (ab 120 ø r6) |

| Shaft tolerance | f7 |

Shaft material

| Material | The difference in hardness to the bearing should be at least 100 HB if possible hardened and ground, roughness ≤ Rz 6,3 |

Mounting advice

| Housing | Installation chamfer, approx. 1.5 mm x 15 to 45° |

| Shaft | Installation chamfer, 5 mm x 15°, edges rounded. |

| Installation mandrel | It is advisable to use a suitable press-in mandrel. It may be necessary to grease the outer surfaces during installation. |

Related links to "BRO - MAS® Cylindrical bushing BSZ"

Viewed